From Detergent Boxes to Perfume Bottles: Versatile Blow Molding Machines for Every Industry

The plastic packaging industry is a dynamic sector characterized by rapid production cycles and ever-evolving product diversity. In this fast-paced environment, variety and speed in packaging are no longer luxuries—they are necessities.

From household cleaning products to food containers, and from cosmetic bottles to industrial packaging, every product requires different shapes, sizes, and plastic materials. To meet these diverse needs efficiently, manufacturers rely on high-speed and versatile blow molding machines.

At Yelkenciler Machines, we empower manufacturers by delivering advanced plastic blow molding machines that increase productivity and offer design flexibility. In this article, we explore the advantages of blow molding technology, its sector-specific applications, and why it’s a smart investment for businesses seeking efficient and scalable solutions.

Why Blow Molding Technology is Ideal for Plastic Bottle Production

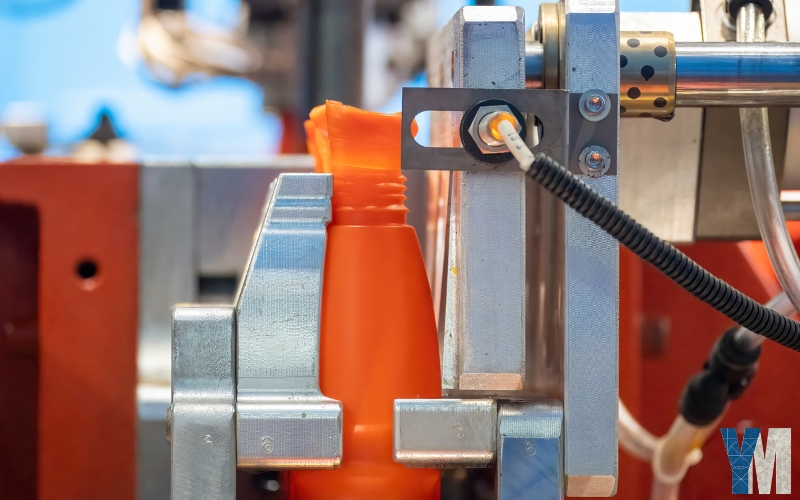

Blow molding involves melting plastic at high temperatures and inflating it inside a mold using air pressure to form the desired shape. This method is compatible with various plastics such as PET, HDPE, PP, and LDPE, making it suitable for a wide range of industries.

Key Benefits of Blow Molding Machines:

-

Flexible production with fast mold changeover capabilities

-

Ability to produce a wide variety of bottle designs and volumes

-

Low production cost and high output rate

-

Automation-friendly systems that reduce human error

Thanks to these features, versatile blow molding machines help businesses achieve both operational efficiency and profitability.

Blow Molding in Detergent Box Production

Detergent boxes are typically produced using HDPE (High-Density Polyethylene), a durable material ideal for packaging household cleaners and industrial chemicals. It provides excellent impact resistance and leak-proof performance—crucial for safe transport and storage.

Yelkenciler Machine’s high-performance blow molding systems are capable of producing HDPE containers from 5 liters to 20 liters. Our flexible mold technology allows for quick adjustments and seamless transitions between different product types, ensuring uninterrupted production.

Precision and Aesthetics in Perfume Bottle Manufacturing

In the cosmetics industry, perfume bottles serve as more than packaging—they represent brand identity and luxury. That’s why high-precision molding is crucial. Our machines are engineered to produce thin-walled, symmetrical, and aesthetically pleasing bottles with clear contours and high surface quality.

These systems are ideal for small-volume cosmetic packaging, delivering leak-proof performance and mold-customization that aligns with your brand’s design language.

Yelkenciler Engineering Content Manager